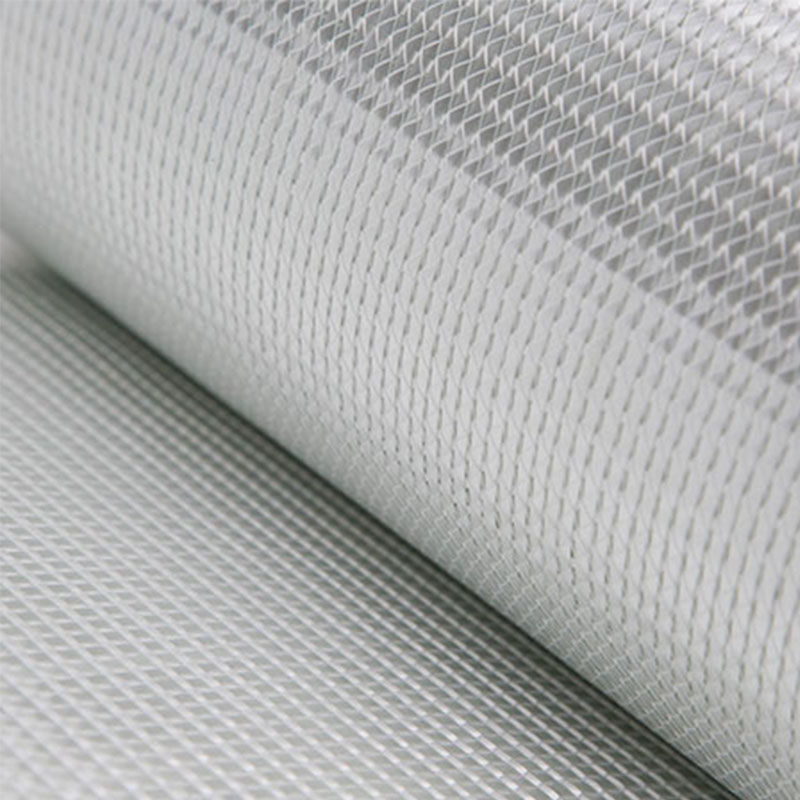

E-glass multi end roving

is especially designed as reinforcements for thermoset resins. The e-glass multi end roving is

coated with a silane-based sizing and

compatible with unsaturated polyester(UP), Vinylester(VE), Epoxy(EO). E-glass multi end roving direct roving is used in filament winding and extrusion process, hand lay-up and woven roving products.E-glass multi end roving can be used to produce FRP pipes and pressure vessels. Main uses include manufacture of FRP pipes of various diameters,high-pressure pipes for petroleum transitions,pressure vessels,storage tanks,and insulation materials such as utility rods and insulation tube.

A: E-Glass Multi End Roving For SMC

1. Brief Introduction

E-glass multi end roving for smc is suitable for reinforcement of up resin, improving the cutting performance of final products, good dispersion and good fluid in the resin, lower fuss, fast impregnation, low static electricity, it can be used for making various kinds of auto parts such as bumper, trunk, door etc. for the building materials field, it can be also used for making smc door, smc chair, sanitary ware, water tank, ceiling etc. for electric field, it can also be used for various kinds of electric parts and electric meters etc.

2. Data Sheet

Model | Rated Size Tex | Deviation % | Moisture Content % | Sizing Content % | Rigidity mm |

ER2400-T717 | 2400 | ±6 | W0.10 | 1.4±0.2 | 160±20 |

ER4800-T717 | 4800 | ±6 | W0.10 | 1.4±0.2 | 160±20 |

Remark: above parameters can be regulated according to the customer's request.

3.

Packing , Storage And Transportation

This E-glass multi end roving is packed in pallets, every single roll is in a shrinkage polybag, 3-4 layers for each carton, or 48-64 rolls/each carton.

The E-glass multi end roving should be stored in the dry and open environment to prevent wetting out and also should be packed completely.

The best storage temperature is 5-35°C, moisture degree is 35-65%, this product is better to be used up in 12 months.

Maximum two layers of pallets is allowed vertically stacked if the storage space is limited.

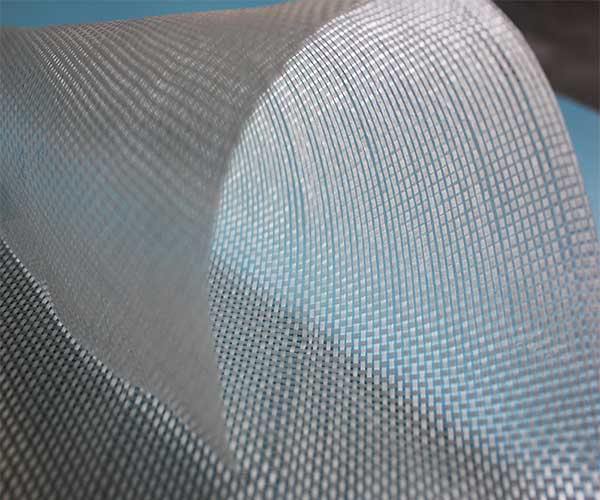

B: E-Glass Direct Roving

1. Brief Introduction

E-glass direct roving is made by advanced tank furnace through high temperature pulling and formed in one procedure, e-glass multi end roving is used for reinforcement of unsaturated polyester resin, vinyl ester resin, epoxy resin etc. it is also with good weaving performance, it can also be used for various kinds of frp products, it can also be used for pultrusion and filament winding.

2. Data Sheet

Model No. | Rated Size Tex | Deviation % | Moisture Content % | Sizing Content % | Strength N/tex |

EDR300-T208 | 300 | ±5 | W0. 2 | 0. 55±0. 2 | NO. 35 |

EDR600-T208 | 600 | ±5 | W0. 2 | 0. 55±0. 2 | NO. 35 |

EDR900-T208 | 900 | ±5 | W0. 2 | 0. 55±0. 2 | NO. 35 |

EDR1200-T208 | 1200 | ±5 | W0. 2 | 0. 55±0. 2 | NO. 35 |

EDR1500-T208 | 1500 | ±5 | W0. 2 | 0. 55±0. 2 | NO. 35 |

EDR2400-T208 | 2400 | ±5 | W0. 2 | 0. 55±0. 2 | NO. 35 |

Remark: above parameters can be regulated according to the customer's request.

3.Packing , Storage And Transportation

This product is packed in pallets, every single roll is in a shrinkage polybag, 3-4 layers for each carton, or 48-64 rolls/each carton.

The product should be stored in the dry and open environment to prevent wetting out and also should be packed completely.

The best storage temperature is 5-35°C, moisture degree is 35-65%, this product is better to be used up in 12 months.

Maximum two layers of pallets is allowed vertically stacked if the storage space limited.

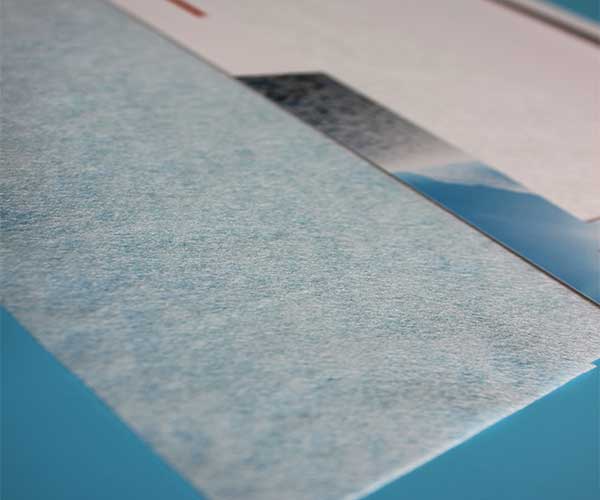

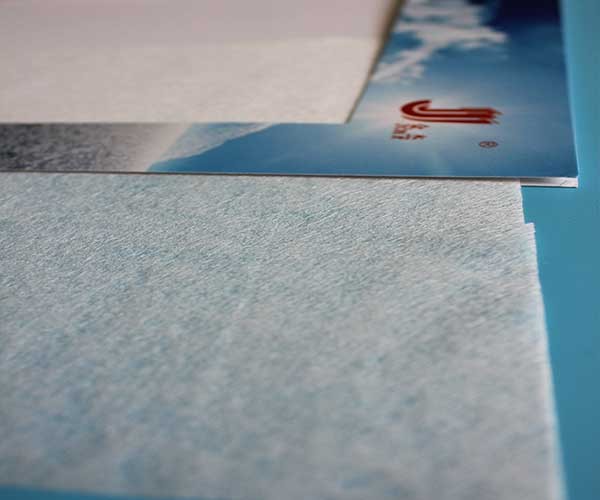

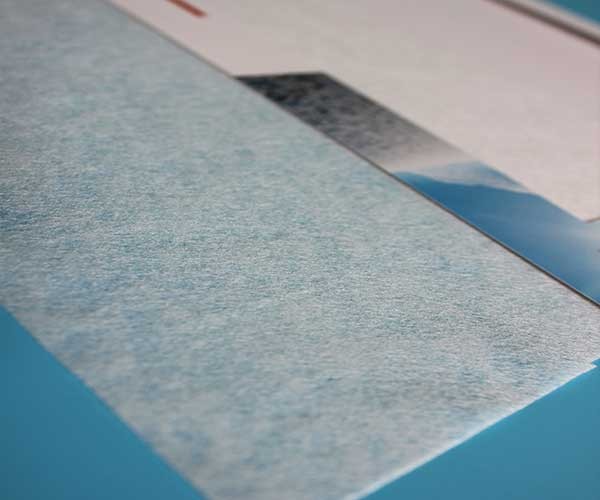

C: E-Glass High Strength Water Cut Chopped Strand

1. Brief Introduction

E-glass high strength water cut chopped strand is suitable for making non woven fibreglass felt(wetting method), polyester cloth etc.

This product is made by off line cutting and coated by special sizing.

This product is easily to be distributed in the plain water and has good compatibility with emulsion binder, the finished product is with high strength.

2. Data Sheet

Model No. | Filament Diameter pm | Cut Length mm | Moisture Content % | Binder Content % |

E11 | 11.0±1.0 | 12、 18、 24 | 6.0-8.0 | NO. 03 |

E13 | 13.0±1.0 | 12、 18、 24 | 6.0~8.0 | NO. 03 |

E17 | 17.0±1.0 | 12、 18、 24 | 6.0~8.0 | NO. 03 |

3.

Packing , Storage And Transportation

This product is packed in 25kgs ribbon bag.

This products storage life is three months under the temperature between 0°C to 25°C.

Maximum two layers of pallets is allowed vertically stacked if the storage space limited.

FAQ

1. How can I get a sample?

Small quality of sample in stock will be free, but the freight will be charged.

2. What is the packing of your fiberglass products?

Mostly, rolls put into carton, then we use the pallet to avoid breakage during delivery.

3. Are you able to customize the width for us?

Yes, but the production time will be a little longer than the general products.

4. Can we use the label of our own?

Yes, we are able to make the label depends on your printing file with your own company logo.

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com