How SMC Composite Material is Revolutionizing Manufacturing

Oct 08, 2023|

Oct 08, 2023| View:125

View:125SMC composite material, also known as Sheet Molding Compound, is making waves in the manufacturing industry with its transformative properties and capabilities. Let's explore how SMC composite material is revolutionizing manufacturing processes and driving innovation across various sectors.

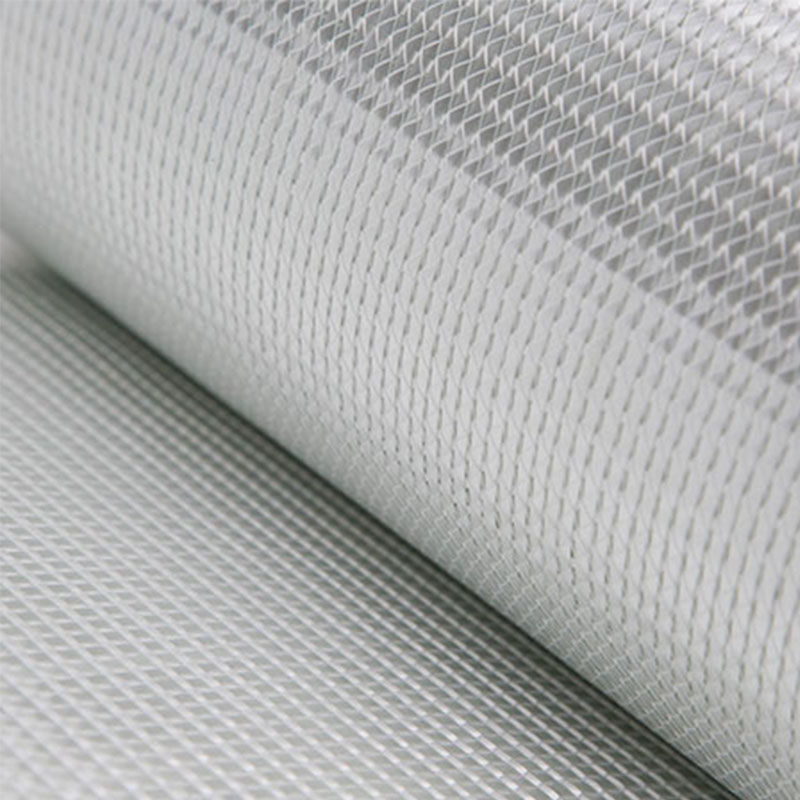

How does SMC composite material differ from traditional materials? SMC composites are composed of a thermoset resin matrix reinforced with glass or carbon fibers, resulting in a lightweight yet robust material. This unique combination offers significant advantages over conventional materials, such as metals and plastics.

One of the key ways SMC composite material is revolutionizing manufacturing processes is through its exceptional strength-to-weight ratio. Despite being lightweight, SMC composites exhibit high strength and stiffness, making them ideal for applications that require structural integrity and reduced weight. This advantage translates into improved fuel efficiency in transportation, increased load-bearing capacity in construction, and enhanced performance in aerospace and marine industries.

Moreover, SMC composite material offers unparalleled design flexibility. It can be easily molded into complex shapes and intricate geometries, allowing designers and engineers to create components with precise specifications and tailored functionalities. This versatility opens up new avenues for innovation, enabling the development of more efficient and advanced products across industries.

Another aspect where SMC composite material shines is in its streamlined manufacturing processes. Due to its low viscosity and excellent flow characteristics, SMC composites can be efficiently molded into desired shapes, resulting in reduced cycle times and enhanced production efficiency. Manufacturers can achieve cost savings and faster time-to-market without compromising on the quality and performance of the final products.

Furthermore, the exceptional durability and resistance of SMC composite material contribute to its revolutionary impact on manufacturing. SMC composites exhibit excellent resistance to corrosion, chemicals, moisture, and UV radiation, ensuring long-term performance even in harsh environments. This durability reduces maintenance costs and extends the lifespan of products, making them more reliable and cost-effective for end-users.

Additionally, SMC composite material aligns with the growing focus on sustainability in manufacturing. Its lightweight nature contributes to energy savings and reduced carbon emissions, promoting a greener and more eco-friendly approach. Furthermore, SMC composites are recyclable, enabling the material to be repurposed and reducing waste, thus supporting a circular economy.

In conclusion, SMC composite material is revolutionizing manufacturing processes in several ways. With its high strength-to-weight ratio, design flexibility, streamlined production, and durability, SMC composites are driving innovation and transforming industries. As manufacturers continue to explore the potential of this remarkable material, we can expect further advancements and a broader range of applications that leverage the benefits of SMC composite material, paving the way for a more efficient, sustainable, and technologically advanced future.

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com