How is unsaturated polyester resin made

Aug 31, 2022|

Aug 31, 2022| View:381

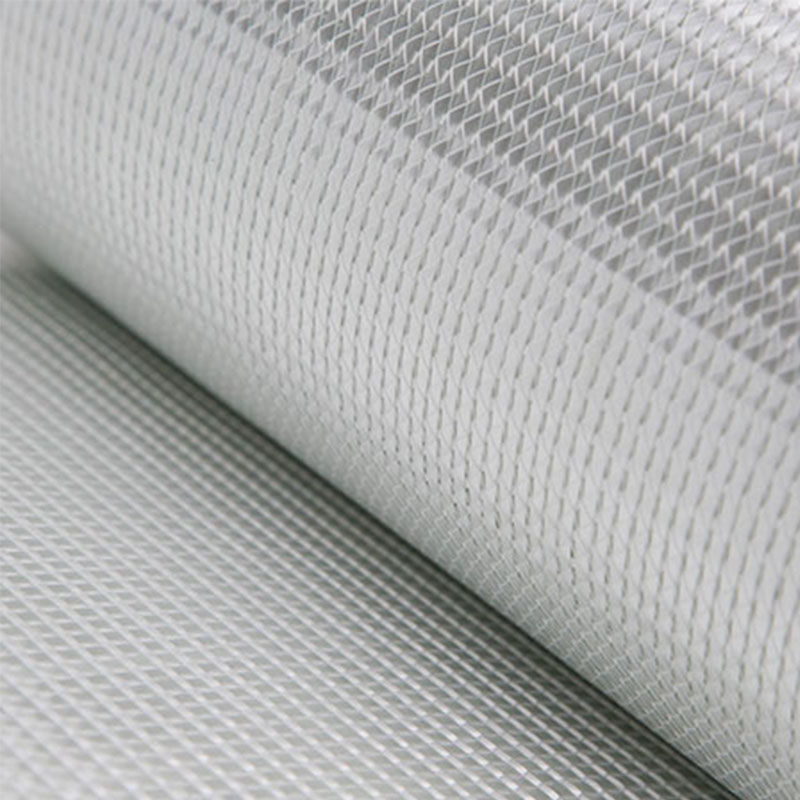

View:381Unsaturated polyester resin is a kind of thermosetting resin, which can be cured into an insoluble polymer network under the action of heat or initiator. However, the mechanical strength of this polymer is very low and cannot meet the requirements of most applications. When reinforced with glass fiber, it can become a composite material, commonly known as "glass fiber reinforced plastic", or FRP for short. The following describes how the unsaturated polyester resin is produced.

The production of unsaturated polyester resin is mainly carried out in three stages:

Polycondensation of dicarboxylic acid and diol is carried out to produce unsaturated long-chain polyester molecules.

The polycondensation product is diluted and dissolved into the unsaturated monomer to become a viscous liquid, which is the resin product. In order to prevent cross-linking and curing of the resin before use or during storage, polymerization inhibitor shall be added to the resin.

The above two steps are generally completed continuously in the resin production process.

In the process of processing and manufacturing various products, initiators and accelerators are added, and mixed with various reinforcing materials and fillers. According to certain process conditions, the resin is crosslinked and cured, and at the same time formed into products of certain specifications and forms.

Rule Composite Material is a unsaturated polyester resin manufacturer. We are specialized in producing high-performance unsaturated polyester resins, glass fiber reinforced composites, SMC BMC materials and other related products. We not only have mature products and technologies, but also have our own unique ideas in technology and marketing innovation. Welcome to consult if you need!

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com