What are the main applications of smc composite material

Jul 26, 2022|

Jul 26, 2022| View:371

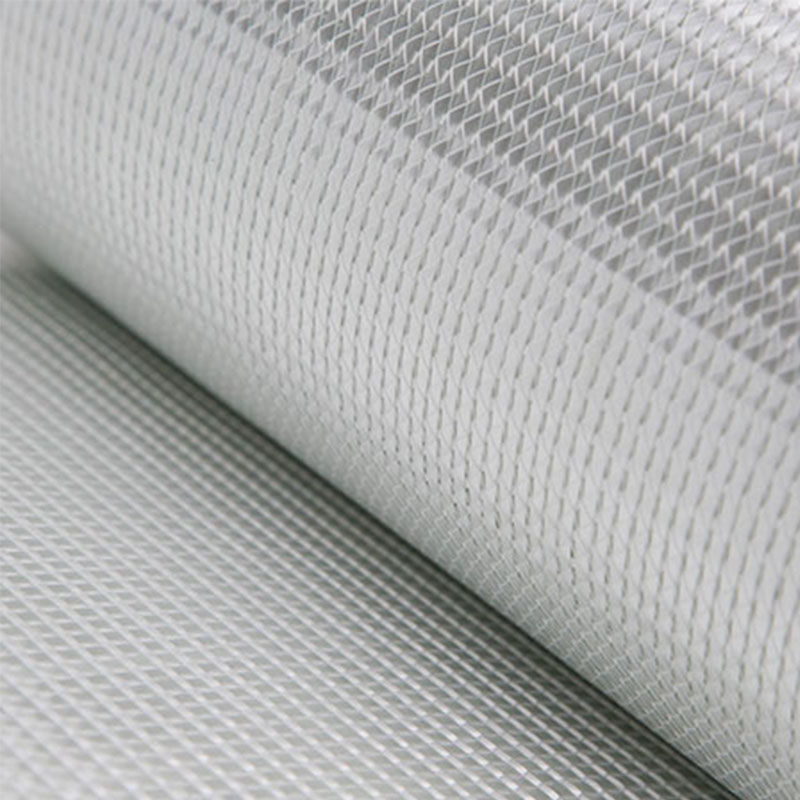

View:371SMC composite material is a common composite material, commonly known as glass fiber reinforced plastics. Its main raw materials are special yarn, fillers and various additives. It first appeared in Europe in the early 1960s, and China introduced foreign advanced SMC production lines and production processes in the late 1980s. So what are the main applications of SMC composite material? Let's give you a specific introduction!

The unique performance of SMC composite material solves the shortcomings of wooden, steel and plastic meter boxes, such as easy aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardancy and short service life. The excellent performance of the composite meter box has absolute sealing and waterproof performance, anti-corrosion performance, anti electric theft performance, no need for grounding wire, beautiful appearance, safety protection with lock and lead seal, long service life, composite cable support, cable trench support Composite meter boxes are widely used in the transformation of rural and urban power networks.

The unique performance of SMC composite material solves the shortcomings of wooden, steel and plastic meter boxes, such as easy aging, easy corrosion, poor insulation, poor cold resistance, poor flame retardancy and short service life. The excellent performance of the composite meter box has absolute sealing and waterproof performance, anti-corrosion performance, anti electric theft performance, no need for grounding wire, beautiful appearance, safety protection with lock and lead seal, long service life, composite cable support, cable trench support Composite meter boxes are widely used in the transformation of rural and urban power networks.

Automotive Industry:

SMC composite material are widely used in automobile manufacturing, involving cars, passenger cars, trains, tractors, motorcycles, sports vehicles, agricultural vehicles and other vehicles. The main SMC components include suspension parts, front and rear bumpers, instrument panels, under bonnet components and so on.

Railway vehicles:

SMC railway vehicle window frames, toilet components, seats, coffee table tops, SMC carriage siding and SMC roof, etc.

Floor material:

The main feature of anti-static SMC floor is that it adopts anti-static SMC composite integral molding technology Moreover, the anti-skid design is adopted on the surface of the product, which has stable anti-static performance, and has the advantages of static electricity conduction, wear resistance, corrosion resistance, aging resistance, fire prevention, compression resistance and so on.

Changzhou Rule Composite Material Co.,Ltd. is a SMC material manufacturers. We are specialized in the research and development, technical consulting and services of composite materials. We can control costs while maintaining high quality and provide customers with the most favorable prices. Not only are our products and technologies mature, but we also have our own unique views on technology and marketing innovation. Welcome to consult if you need!

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com