What is the molding process of RTM resin

Jul 27, 2022|

Jul 27, 2022| View:442

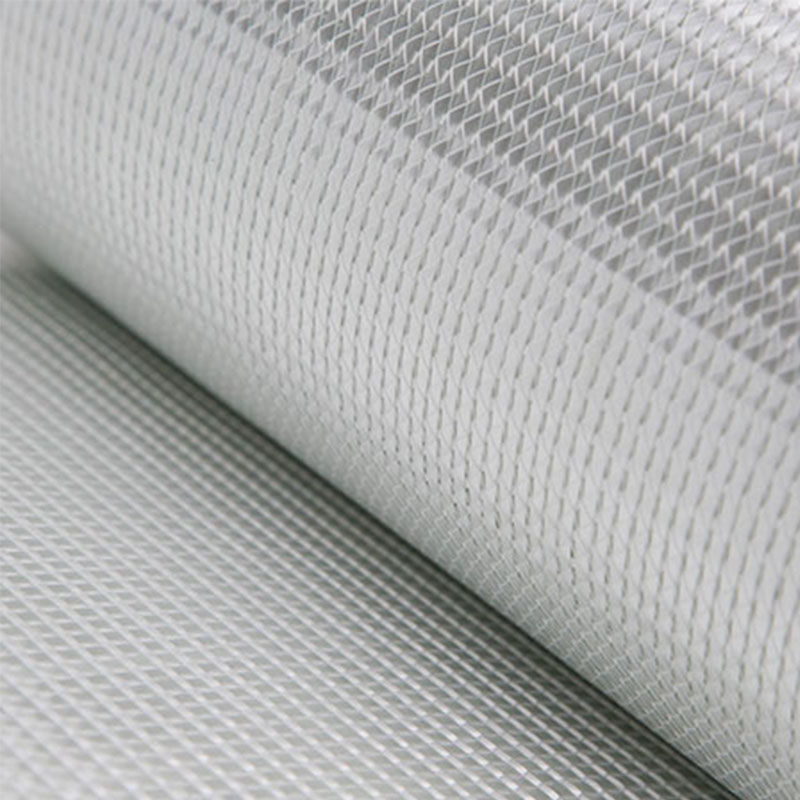

View:442RTM resin refers to a process technology in which low viscosity resin flows, soaks reinforcement materials and solidifies in a closed mold. It belongs to the liquid forming of composite materials or structural liquid forming technology. The specific method is to put reinforcement materials that have been reasonably designed, cut or mechanically preformed into the designed mold in advance, and the mold needs to be sealed and fastened around to ensure the smooth flow of resin; After the mold is closed, the quantitative resin is injected, and the desired product can be obtained by demoulding after the resin is cured.

SMC, BMC molding, injection molding, RTM, VEC technology are all closed mold molding processes. Due to the formulation of environmental law and the improvement of product requirements, open mold composites are increasingly restricted, which promotes the application of closed mold technology, especially in recent years, promotes the innovation and development of RTM technology.

RTM resin molding process mainly has the following characteristics:

1.According to the requirements of production scale, different materials and different grades of molds can be used, which can minimize the cost and obtain better economic benefits.

2.It is a closed mold resin injection method, which can minimize the toxicity of harmful components such as resin to human body and the environment, and meet the requirements of environmental protection.

3.Using low viscosity fast curing resin, RTM Mold can be heated in the production process, so as to further improve production efficiency and product quality.

4.It is conducive to the preparation of large and medium-sized, complex shape, smooth on both sides of the overall structural parts, with good dimensional accuracy, high surface quality and good mechanical properties.

Changzhou Rule Composite Material Co., Ltd is a manufacturer specializing in the production and sales of RTM resin. We can control costs while maintaining high quality and provide customers with the most favorable prices. Welcome to consult if you need!

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com