Introduction and application of pultrusion process

May 10, 2023|

May 10, 2023| View:245

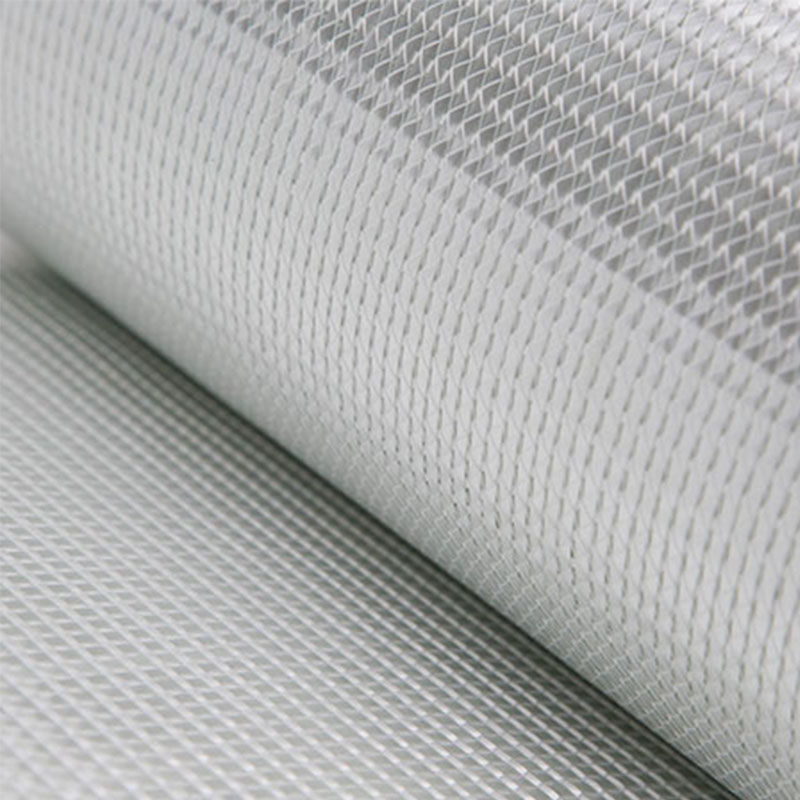

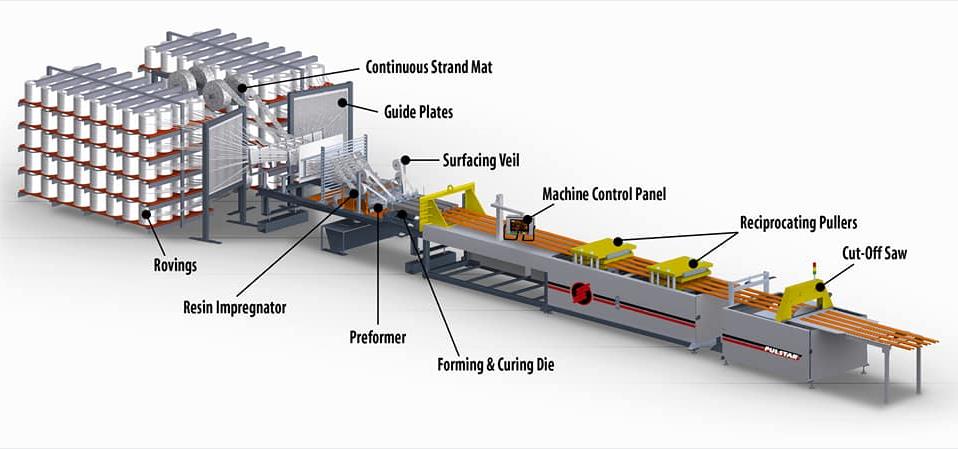

View:245Pultrusion is a composite synthesis process where a constant cross-section and production rate is obtained. In this process the fibers are pulled through a heated die. While passing through the die, a constant pressure is applied, resulting in the resin melting and its impregnation into the fibrous reinforcement.

Pultrusion Radome

(1)General Radome

The function of the radome is to protect the antenna system from the external environment (such as wind and snow, sunlight, creatures, etc.), prolong the life of the antenna, and at the same time, it is necessary to ensure the permeability of electromagnetic waves.

Therefore, the radome material should meet the requirements of dielectric properties, mechanical properties, weather resistance, manufacturability and weight. We adopt a low-medium-high compound rapid curing pultrusion technology system, and the product is suitable for the antenna cover of the existing communication base station.

(2)5G Radome

5G networks use higher frequency bands than 4G networks: 3.3-3.6GHz, 4.8-5.0GHz and 20GHz. The radome is used as the protective shell of the base station antenna, and its dielectric properties are an important factor affecting the quality of 5G signal transmission. Therefore, the radome material needs to adopt the material with low dielectric constant and low dielectric loss.

At the same time, the multi-frequency coexistence of 5G communication (3G, 4G, 5G) leads to an increase in the size of the antenna, which requires the antenna cover to have higher strength and modulus.

In order to avoid antenna hoisting and save installation time and cost, the weight of the multi-frequency antenna needs to be controlled within 50kg.

In order to meet the design requirements of 5G antennas, radome materials will also be developed towards lightweight.We have conducted research on these new requirements and proposed a radome product solution with low dielectric constant, low dielectric loss, weather resistance, high strength, high modulus, and environmental friendliness.

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com