Pultrusion resins: driving the trend toward lighter weight vehicles

May 23, 2023|

May 23, 2023| View:280

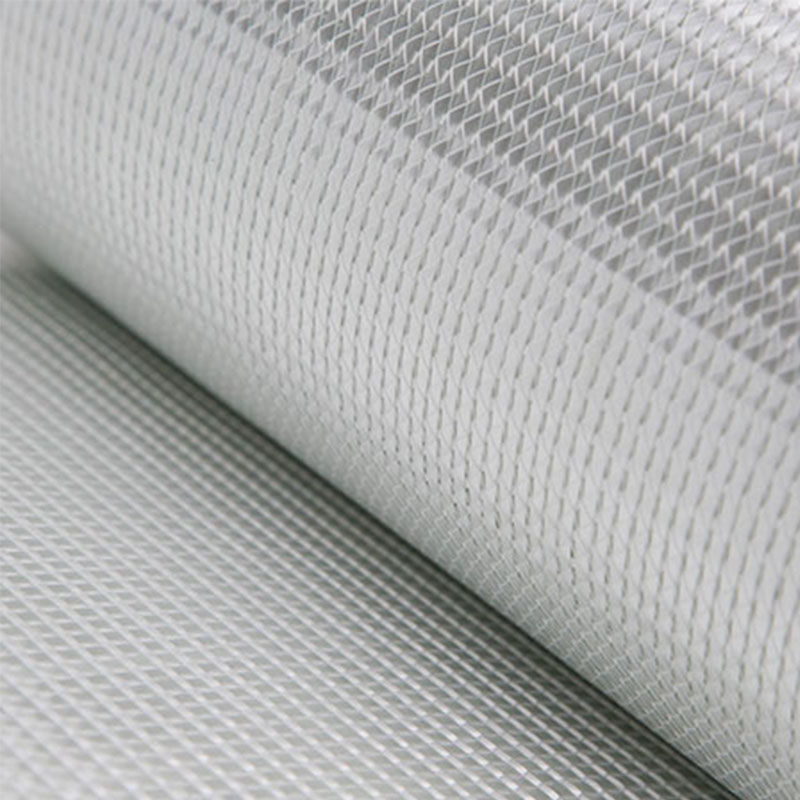

View:280Pultrusion resin is an increasingly popular composite material in the automotive industry. It is a thermoset polymer reinforced with fibers, making it an ideal material for lightweight applications. The use of pultrusion resins is designed to meet the automotive lightweighting trend, which focuses on reducing vehicle weight to improve fuel efficiency and reduce emissions. In this article, we will discuss the advantages and challenges of using pultrusion resins in the automotive industry.

Pultrusion resin offers several advantages over traditional materials such as steel and aluminum. It is lighter, stronger and more durable, offering greater design flexibility and improved performance. The properties of pultrusion resin can be tailored to specific requirements, making it an ideal material for a variety of automotive applications, including body panels, chassis components and interior trim parts.

Key benefits of using pultrusion resins in automobiles:

(1) Weight reduction.

The lightweight nature of pultrusion resins allows them to reduce the weight of a vehicle, which is critical to improving fuel efficiency and reducing emissions. According to research, a 10% reduction in vehicle weight can result in a 6-8% improvement in fuel efficiency. This means significant cost savings for consumers and a reduced environmental impact.

(2) Excellent corrosion and fatigue resistance.

Over time, traditional materials such as steel and aluminum tend to rust and wear, which can compromise the integrity of the vehicle. Pultrusion resins, on the other hand, are highly resistant to corrosion and fatigue, ensuring long-lasting performance and durability.

Despite the many advantages of pultrusion resins, there are some challenges to their use in the automotive industry:

(1) Production cost.

Pultrusion resin is still a relatively new material, and its manufacturing process is complex and expensive. As a result, the cost of producing pultrusion resin components can be higher than traditional materials.

(2) Lack of industry standardization.

As different manufacturers use different materials and processes, ensuring consistency in quality and performance can be challenging. This can lead to fit and finish issues that can compromise the overall integrity of the vehicle.

Despite these challenges, the use of pultrusion resins in the automotive industry is growing. As manufacturers look for ways to reduce weight and improve fuel efficiency, pultrusion resins are becoming an increasingly popular choice for a variety of applications. As technology continues to evolve, we can expect more advances in the production and application of pultrusion resins in the future.

In conclusion, pultruded molding resins are a promising material for the automotive industry and have the potential to revolutionize the way cars are designed and manufactured. While some challenges remain with its use, their benefits outweigh the costs. The light weight and durability of pultrusion resins make them ideal for reducing vehicle weight and improving fuel efficiency. We expect the use of pultrusion resins to increase significantly in the coming years as manufacturers continue to explore new and innovative ways to incorporate this material into their designs. For more detailed information, please feel free to contact us!

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com