Sheet Molding Compounds (SMC)

Jun 19, 2023|

Jun 19, 2023| View:206

View:206Sheet Molding Compound Offers Superior Strength and Electrical Insulation

Manufacturing Process of SMC

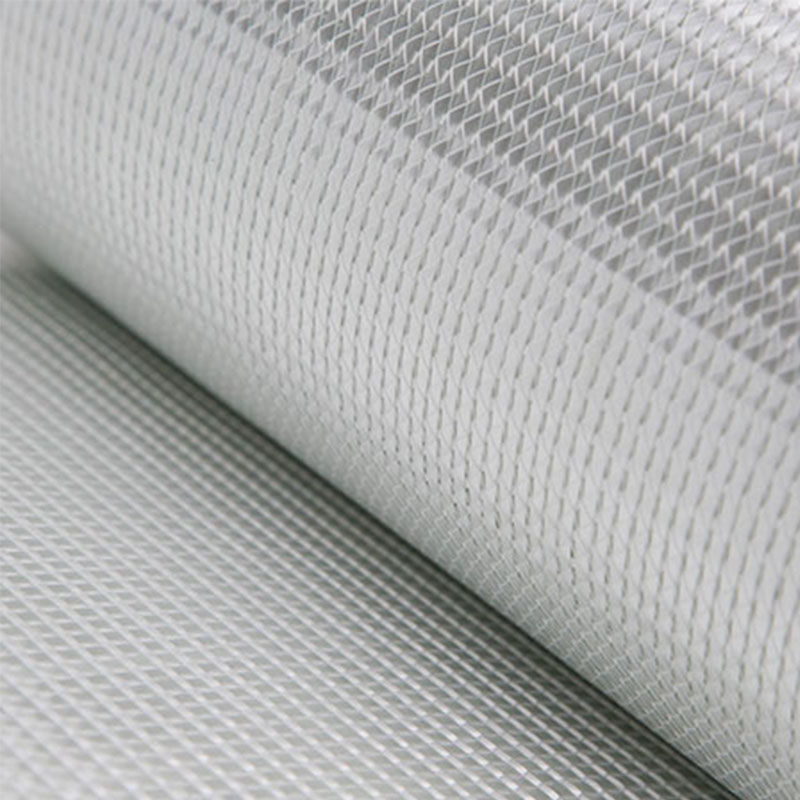

Thermoset Sheet Molding Compound (SMC) is a mixture of polymer resin, inert fillers, fiber reinforcement, catalysts, pigments and stabilizers, release agents, and thickeners and possesses strong dielectric properties. Manufacture of sheet molding compounds is a continuous in-line process. The material is sheathed both top and bottom with a polyethylene or nylon plastic film to prevent auto-adhesion. The paste is spread uniformly onto the bottom film. Chopped glass fibers are randomly deposited onto the paste. The top film is introduced and the sandwich is rolled into a pre-determined thickness. The sheet is allowed to mature for 48 hours.

Applications and Advantages

Sheet molding compounds can be molded into complex shapes. Superior mechanical properties and surface appearance, plus excellent electrical insulation make this thermoset material ideal for automotive Class A body panels, high-strength electrical parts, business equipment cabinets, personal watercraft, and various structural components.

Sheet Molding Compound (SMC) is a compression molding compound often used for larger parts where higher mechanical strength is needed. SMC is a fiber reinforced thermoset material. Glass reinforcement is between 10% and 60%, and glass length is slightly longer than Bulk Molding Compound (BMC) - between 1/2-inch and 1-inch (25mm).

Manufacturing Process of SMC

Thermoset Sheet Molding Compound (SMC) is a mixture of polymer resin, inert fillers, fiber reinforcement, catalysts, pigments and stabilizers, release agents, and thickeners and possesses strong dielectric properties. Manufacture of sheet molding compounds is a continuous in-line process. The material is sheathed both top and bottom with a polyethylene or nylon plastic film to prevent auto-adhesion. The paste is spread uniformly onto the bottom film. Chopped glass fibers are randomly deposited onto the paste. The top film is introduced and the sandwich is rolled into a pre-determined thickness. The sheet is allowed to mature for 48 hours.

Applications and Advantages

Sheet molding compounds can be molded into complex shapes. Superior mechanical properties and surface appearance, plus excellent electrical insulation make this thermoset material ideal for automotive Class A body panels, high-strength electrical parts, business equipment cabinets, personal watercraft, and various structural components.

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com