What is Pultrusion Resin and Its Vital Role in Composite Manufacturing?

Jun 29, 2023|

Jun 29, 2023| View:211

View:211

Pultrusion resin plays a crucial role in manufacturing composite materials through the pultrusion process. As a fundamental component, this specialized resin system enables the production of strong, lightweight, and durable composite profiles. In this article, we will explore what pultrusion resin is, its significance in composite manufacturing, and how it contributes to producing high-performance composite products.

1. Understanding Pultrusion Resin:

A. Definition:

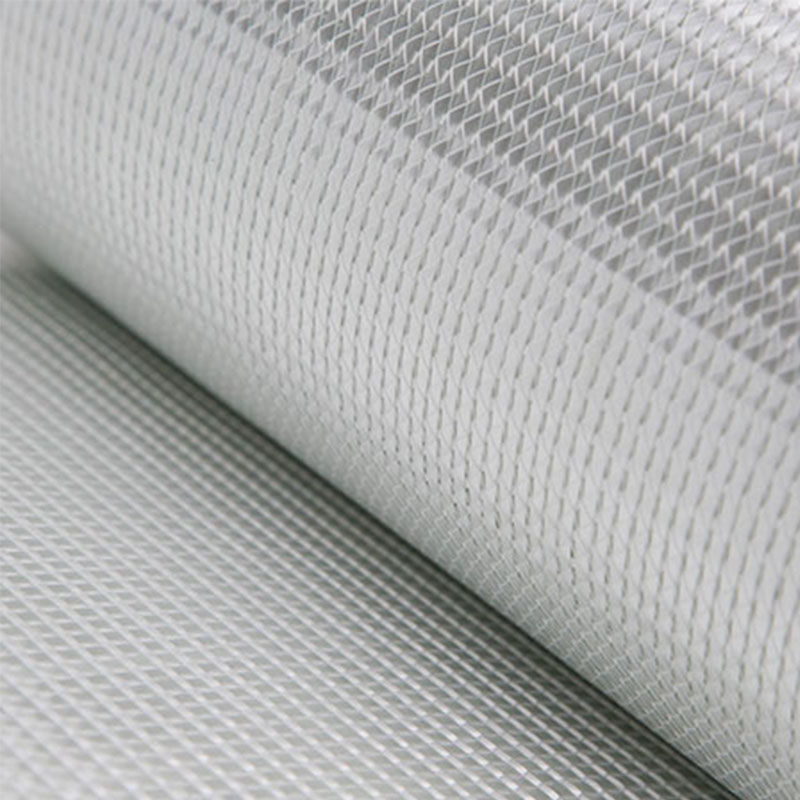

Pultrusion resin is a formulated polymer matrix system specifically designed for pultrusion. A combination of liquid resin and other additives provides the necessary properties for impregnating reinforcing fibers and forming composite structures.

B. Key Properties:

Pultrusion resin possesses several essential properties. It exhibits excellent wetting and impregnation capabilities, ensuring the complete saturation of reinforcing fibers. Additionally, it offers good adhesion to the fibers, facilitating the transfer of loads and enabling effective stress distribution within the composite material.

2. Role of Pultrusion Resin in Composite Manufacturing:

A. Fiber Impregnation:

Pultrusion resin plays a vital role in thoroughly impregnating the reinforcing fibers, typically fiberglass, with the resin matrix. Through the pultrusion process, the resin is carefully applied to the continuous fibers, ensuring uniform distribution and complete wetting. This impregnation process is critical for achieving the desired mechanical properties of the final composite product.

B. Matrix Formation:

Once impregnated, the pultrusion resin undergoes a curing process to solidify and form the matrix that binds the reinforcing fibers together. The resin undergoes a chemical reaction during curing, resulting in a hardened and durable matrix. This matrix provides structural integrity, strength, and stability to the composite material.

C. Mechanical Performance:

Pultrusion resin significantly influences the mechanical properties of the final composite product. Manufacturers can tailor the composite's strength, stiffness, impact resistance, and other desired characteristics by selecting the appropriate resin system to meet specific application requirements. The pultrusion resin ensures consistent and reliable mechanical performance, making it suitable for various industries.

3. Advantages and Applications of Pultrusion Resin:

A. Lightweight and High Strength:

Pultrusion resin enables the production of lightweight composite profiles with exceptional strength-to-weight ratios. This advantage makes it a preferred choice in construction, aerospace, automotive, and marine industries, where weight reduction is critical.

B. Corrosion Resistance:

Composite materials manufactured using pultrusion resin exhibit excellent resistance to corrosion, chemicals, and environmental factors. This attribute makes them ideal for applications exposed to harsh environments, such as infrastructure, chemical processing, and offshore structures.

C. Design Flexibility:

Pultrusion resin allows for the creation of complex shapes and customized profiles. The resin's flow and curing characteristics facilitate the production of intricate geometries, opening up various design possibilities for engineers and architects.

Pultrusion resin is a vital component in manufacturing high-performance composite materials through the pultrusion process. Its ability to impregnate and bind reinforcing fibers and its favorable mechanical properties make it indispensable for various industries. If you require top-quality pultrusion resin, please feel free to contact us. We are committed to providing tailored resin solutions to meet your composite manufacturing requirements.

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com