Bulk Molding Compounds (BMC)

Jul 19, 2023|

Jul 19, 2023| View:228

View:228

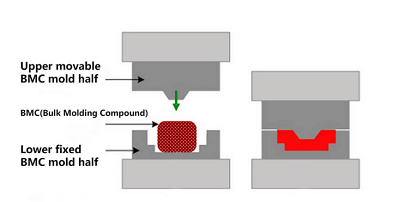

Manufacturing Process of BMC

Bulk Molding Compound Offers Excellent Flow Characteristics

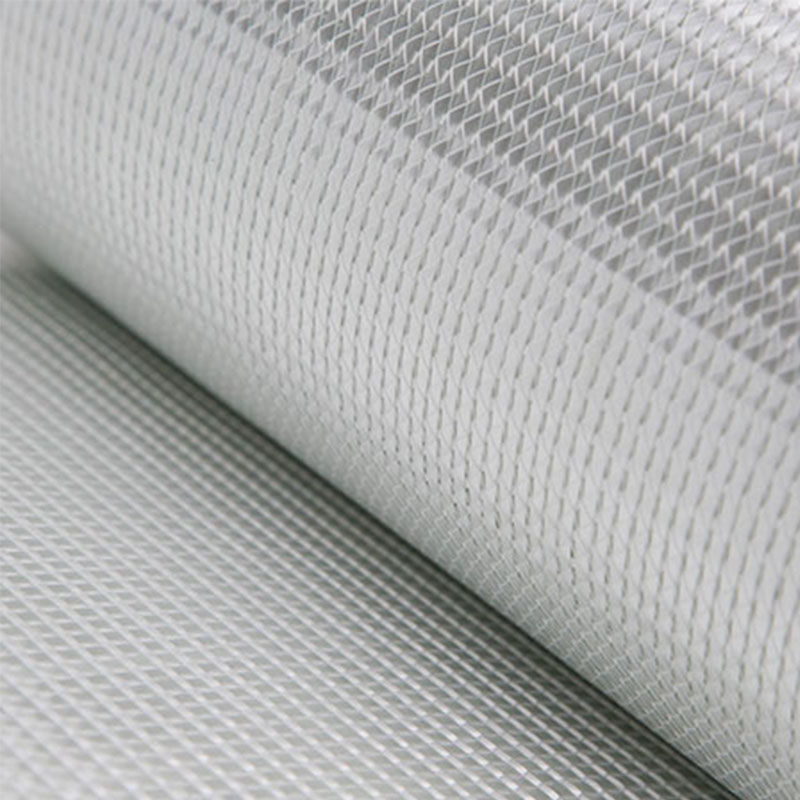

BMC is manufactured by mixing strands (Greater than 1/8” and less than 2") of chopped glass fibers, styrene, an initiator, and filler in a mixer with an unsaturated thermoset resin (commonly polyester resin, vinyl ester resin or epoxy resin). The mixing is done at room temperature and stored at low temperatures to slow down curing prior to molding. The concentration of the mixture can vary depending on application, but is typically 30% glass fibers, 25% filler, and 45% resin, styrene, and initiator. The material is provided in bulk or in logs approximately 4" in diameter.The glass fibers in BMC increase the strength properties of the product to be higher than standard thermoplastic products.

Applications and Advantages

Depending on the end-use application, bulk molding compounds are formulated to achieve close dimensional control, flame and track resistance, electrical insulation, corrosion and stain resistance, superior mechanical properties, low shrink, and color stability. Its excellent flow characteristics, dielectric properties, and flame resistance make this thermoset material well-suited to a wide variety of applications requiring precision in detail and dimensions as well as high performance. The material is available in a broad selection of colors, and can tolerate powder-coat or water-based paint.

salesyomi@rulecomposite.com

salesyomi@rulecomposite.com